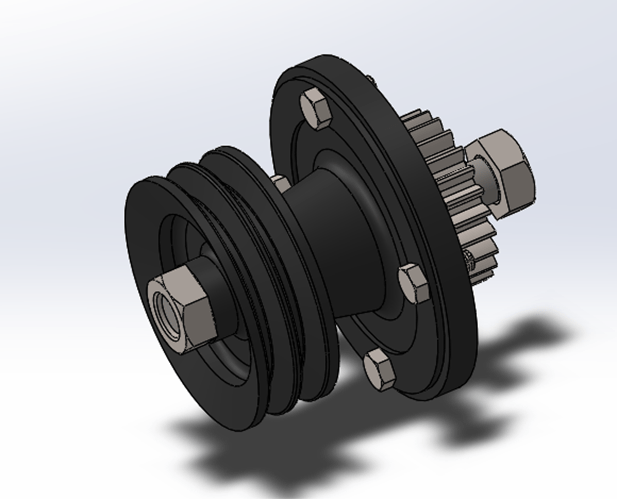

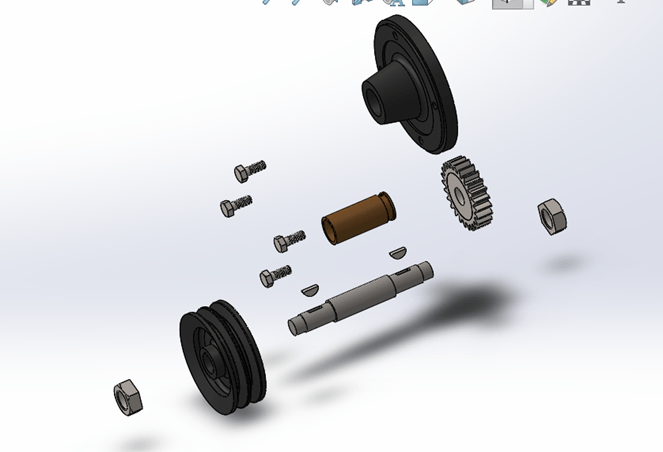

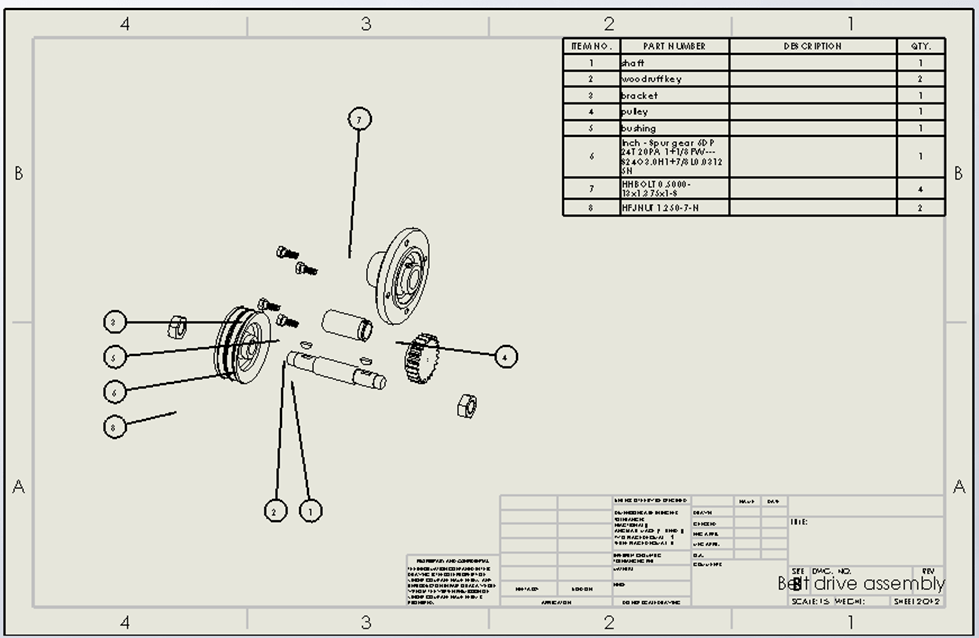

The assigned assembly, the belt drive assembly, consists of (6) individually created parts—

- Pulley

- Bracket

- Shaft

- Bushing

- Woodruff key

- Spur gear

and (3) parts

- Spur gear

- Hex bolt

- Hex jam nut

which can be pulled from the SolidWorks design library. The base of the entire assembly is the solid shaft which was easily created with circular sketches extruded to the specified dimensions. Using ANSI standards for keyset dimensions for woodruff keys, the keyseats were cut from the shaft (one cut, mirrored about the symmetric plane) in order to fit the appropriate woodruff key (#1008). Similar to the shaft, the woodruff key was first a circular sketch, extruded to the appropriate width. The remaining created parts are designed to be around the shaft and therefore have circular holes through the center. This, along with the section assembly drawing given, suggested that the best way to create these parts were to sketch them with respect to half of the section view and revolve the sketch about the main assembly axis. Any holes needed can be cut after the revolved extrude. The holes on the bracket were made to fit the specified hex bolts using the Hole Wizard* tool—one hole was made and then used as the base for the circular pattern about the center axis, creating 4 holes in total. This same technique of circular patterns was used to assemble and mate the hex bolts to the holes. The spur gear from the design library was configured to the appropriate specifications; changes were made using the equations and relations. Finally, the hex jam nut was added at the end of the assembly from the design library, and it was also configured to the drawing specifications. In the assembly, one nut was added and mated and the second was a mirror of the first. From the assembly drawing given, it’s clear that the assembly and corresponding mates are fitted well, consisting of faces being coincident with each other. Additionally, all the components, save for the woodruff keys, are centered around the same axis, creating a relatively easy assembly

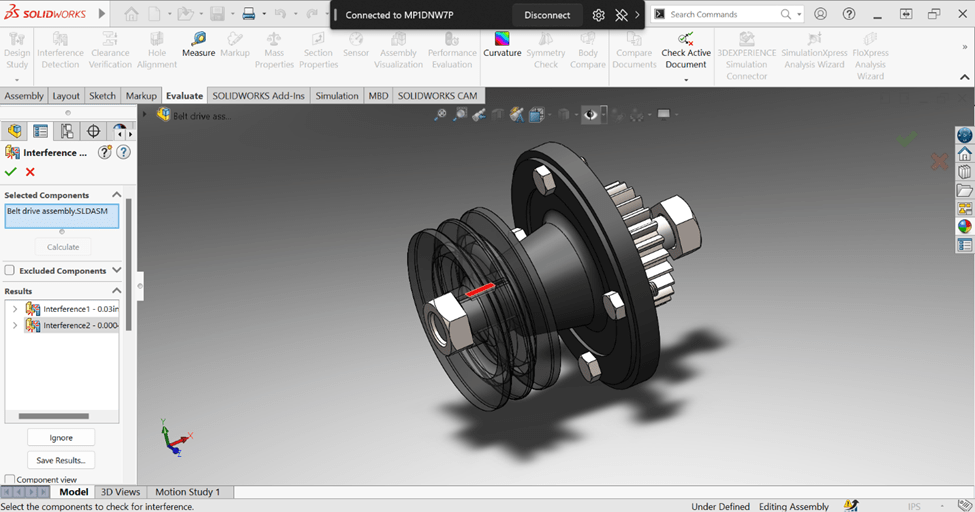

Two interferences were discovered during the analysis—both are the woodruff keys and the corresponding part around it (the pulley in the front and the spur gear in the back). These could have been fixed by adjusting the keyseat hubs on the pulley and the spur gear to the standard sizes from the given stables; because there are allowable tolerances, it would be good to adjust them within that range (in this case, closer to the maximum to allow for the most space).