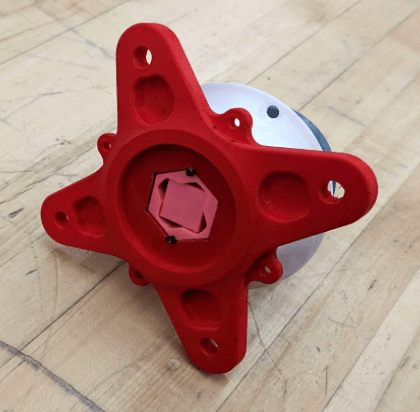

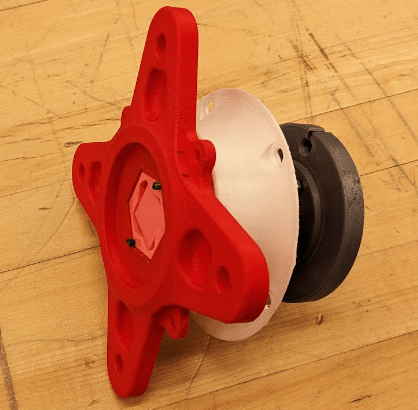

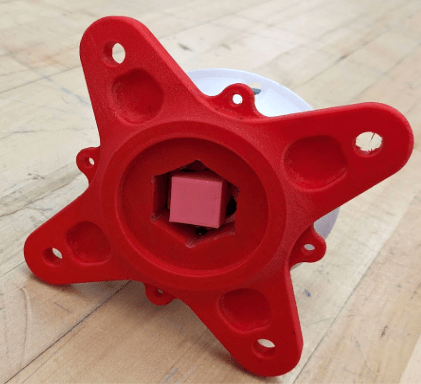

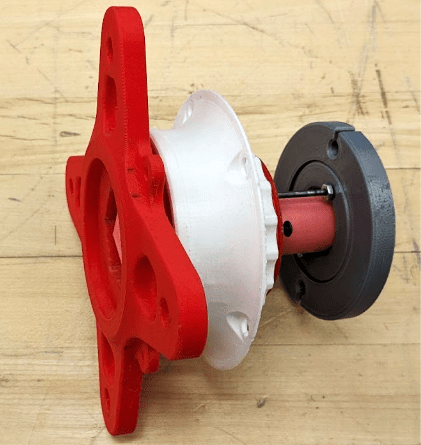

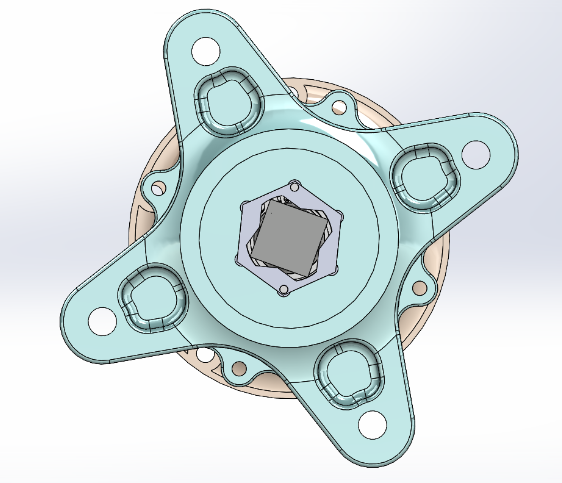

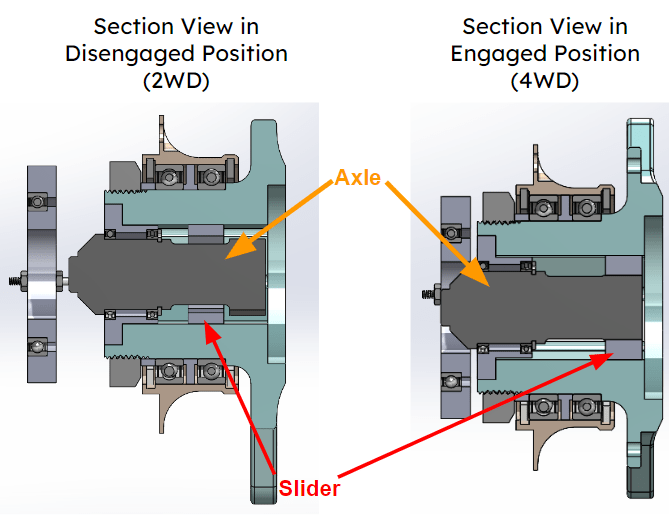

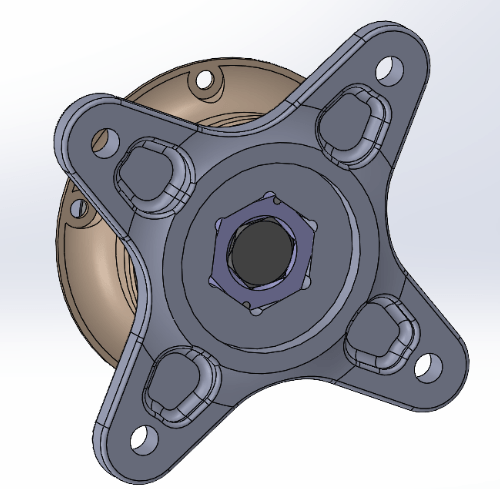

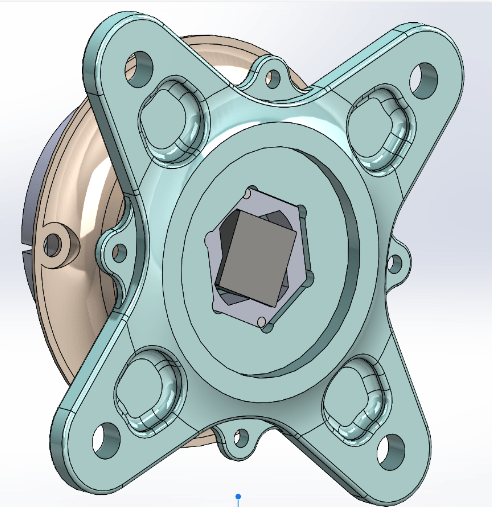

For my capstone project at NJIT, my group and I designed a manual-locking hub cap to be used for the SAE Baja car. The hub cap was designed to allow the car to switch between 4WD and 2WD without completely removing the wheels through purely mechanical means. This mechanism, which could be manufactured completely in-house at our Makerspace, would not only save time at competition but also help save money as the team wouldn’t have to invest in costly electric/pneumatic systems or incompatible WARN hubcaps.

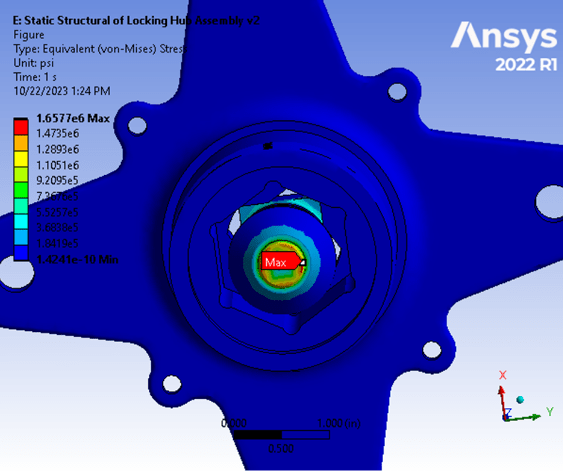

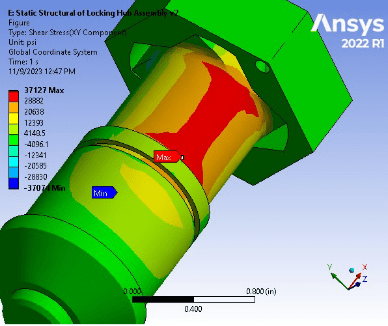

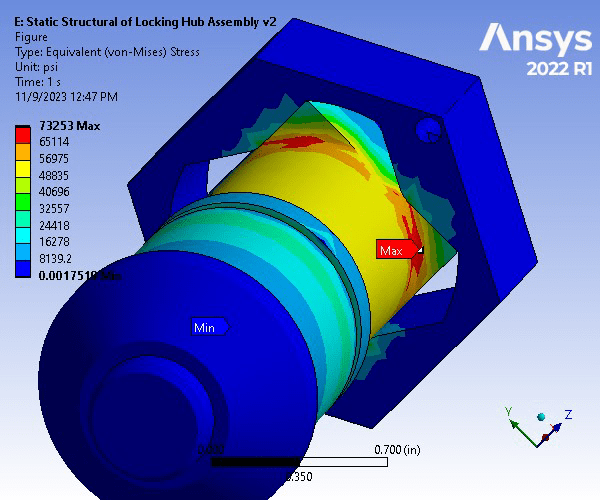

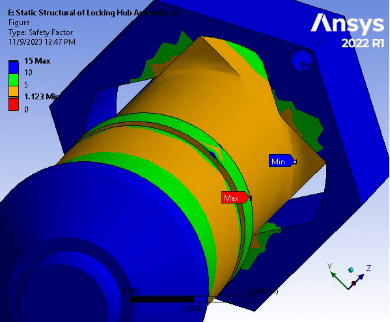

The hub cap design consists of 17 parts, with 8 standard parts. Thus, it would be difficult to analyze the performance of the mechanism purely by hand calculations. By conducting FEA studies on the mechanism, I was able to find where the maximum stresses would likely occur and which parts would fail at the worst-case torque loading. Based on the initial design results, our design lead was able to make design changes to ensure a safer and more practical design.

Using the data, I conducted a materials study on the parts of interest and found which materials would be suitable for each part, helping create the design stronger and more cost efficient. Through these methods, my group was able to test the mechanism without having to build it first, saving both time and resources. A model of the final design was 3D printed and assembled.