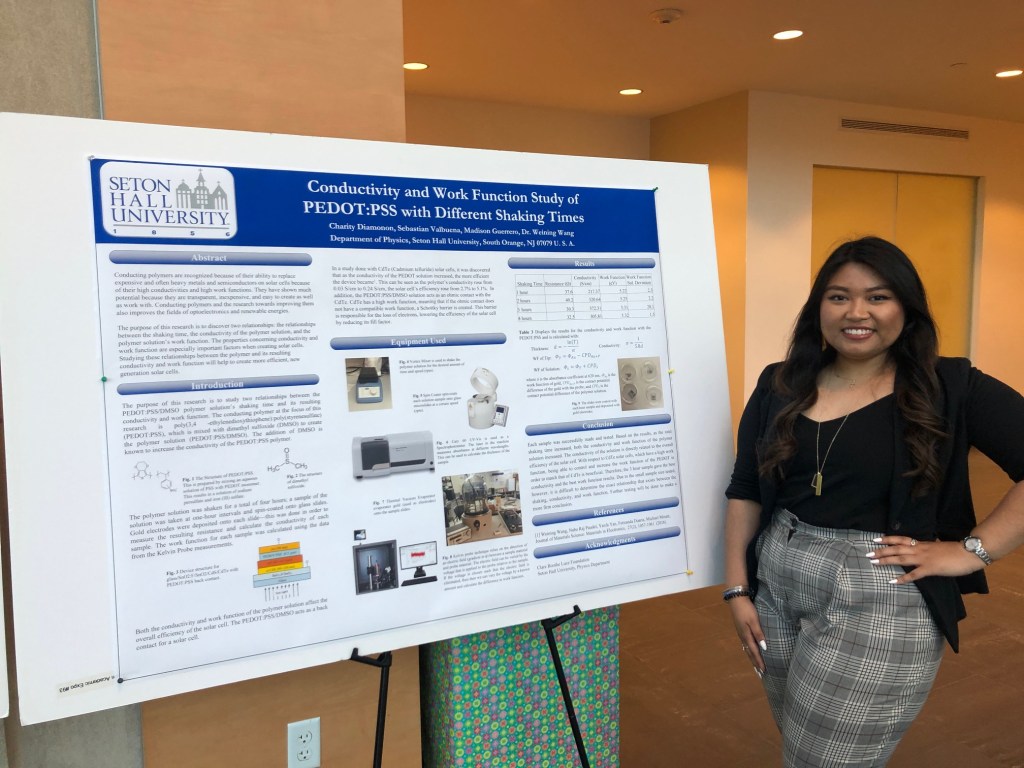

I was an undergraduate researcher under the mentorship of Dr. Weining Wang for the Department of Physics at Seton Hall University from 2018-2020. Our research lab focused on further developing organic new-generation solar cells. My research was focused on studying how manufacturing factors could affect the resulting efficiencies of organic polymer-based solar cells.

Publications featured on this page include:

Conductivity and Work Function Study of PEDOT:PSS with Different Shaking Times

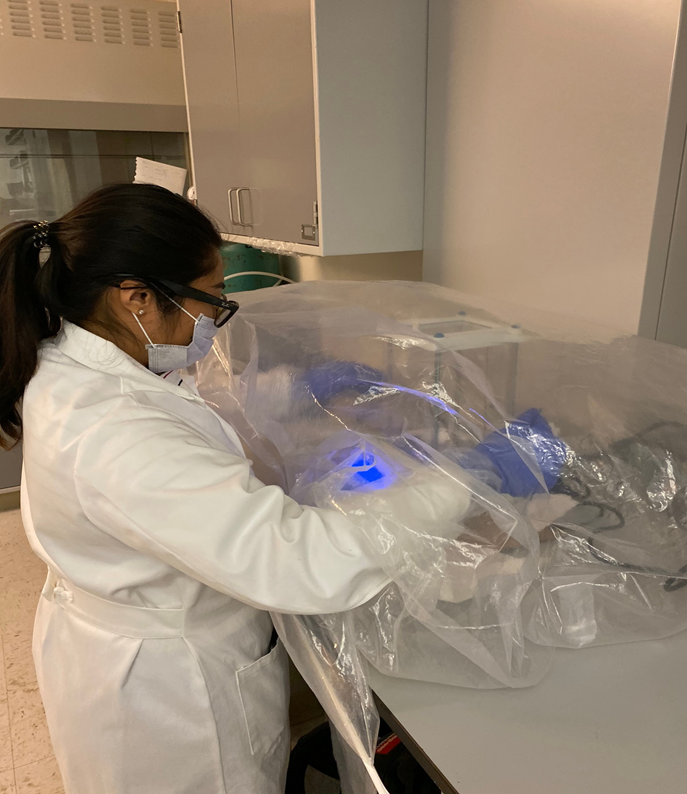

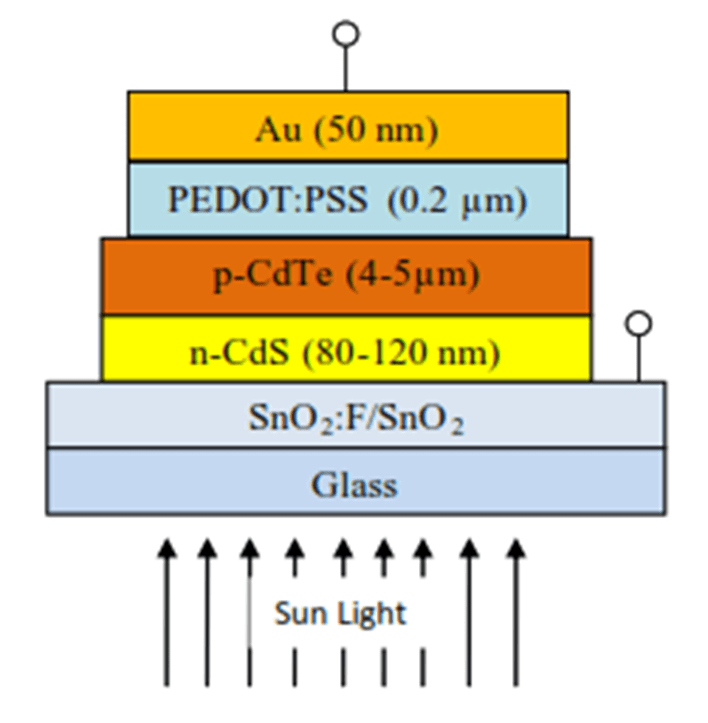

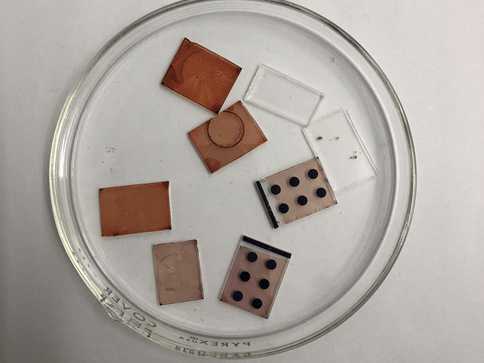

The polymer solution of poly(3,4 -ethylenedioxythiophene):poly(styrenesulfate) (PEDOT:PSS), which is mixed with dimethyl sulfoxide (DMSO) to create the polymer solution (PEDOT:PSS/DMSO), was shaken for a total of four hours; a sample of the solution was taken at one-hour intervals and spin-coated onto glass slides. Gold electrodes were deposited onto each slide—this was done in order to measure the resulting resistance and calculate the conductivity of each sample. The work function for each sample was calculated using the data from Kelvin Probe measurements. In a previous study done with CdTe (Cadmium telluride) solar cells [1], it was discovered that as the conductivity of the PEDOT solution increased, the more efficient the device became. In addition, the PEDOT:PSS/DMSO solution acts as an ohmic contact with the CdTe. CdTe has a high work function, meaning that if the ohmic contact does not have a compatible work function, a Schottky barrier is created. This barrier is responsible for the loss of electrons, lowering the efficiency of the solar cell by reducing its fill factor.

PEDOT:PSS back contact.

| Shaking Time | Resistance (Ω) | Conductivity (S/cm) | Work Function (eV) | Work Function Std. Deviation |

| 1 hour | 37.6 | 217.37 | 5.22 | 2.3 |

| 2 hours | 40.2 | 320.64 | 5.25 | 2.2 |

| 3 hours | 30.3 | 372.31 | 5.31 | 28.1 |

| 4 hours | 32.5 | 305.81 | 5.32 | 1.5 |

Based on the results, as the total shaking time increased, both the conductivity and work function of the polymer solution increased. The conductivity of the solution is directly related to the overall efficiency of the solar cell. Although it may seem that a higher work function would be detrimental to the efficiency of the solar cell, with respect to CDTE solar cells, which have a high work function, being able to control and increase the work function of the PEDOT in order to match that of the CDTE is beneficial. Therefore, the 3 hour sample gave the best conductivity and the best work function results. Due to the small sample size tested, however, it is difficult to determine the exact relationship that exists between the shaking, conductivity, and work function. Further testing will be done to make a more firm conclusion.

Influence of Spin-Coating Speed and Mixing Ratio on Polymer-Fullerene Films

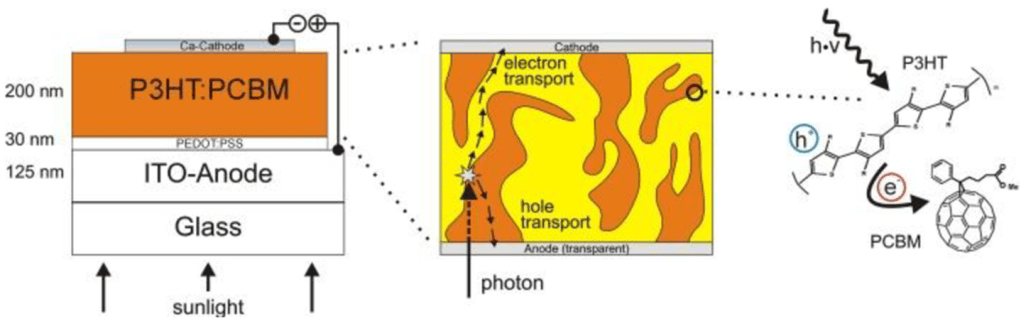

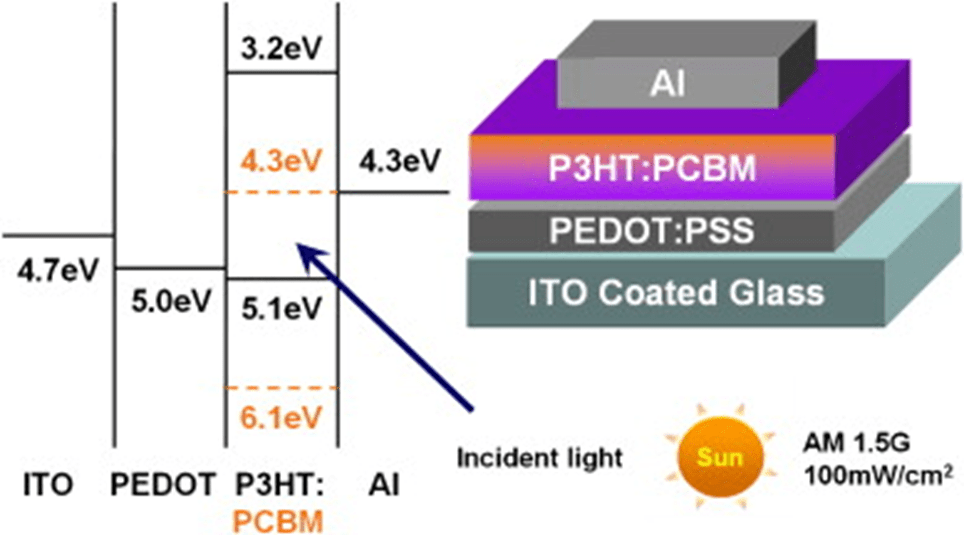

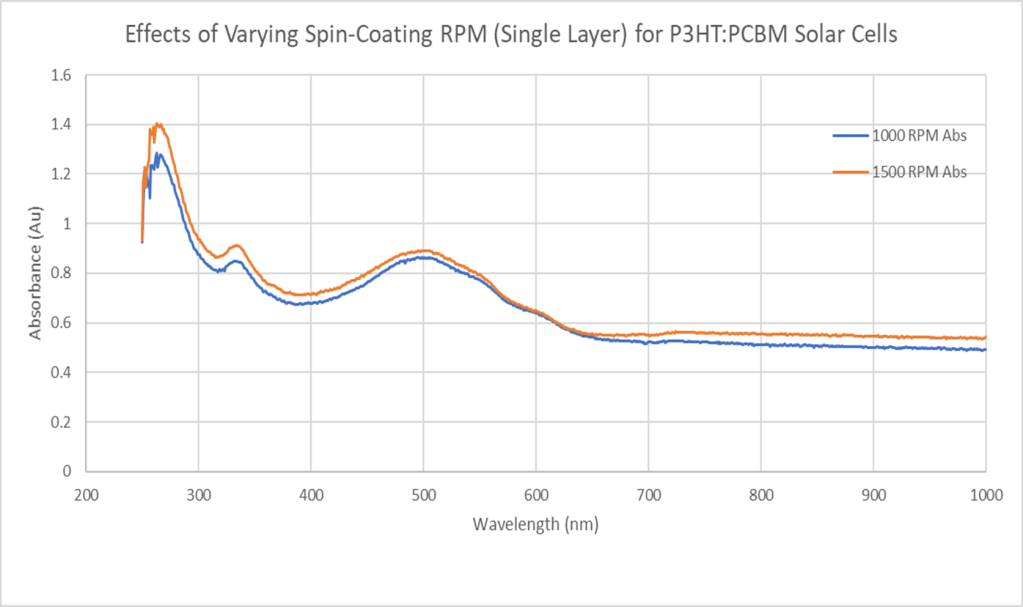

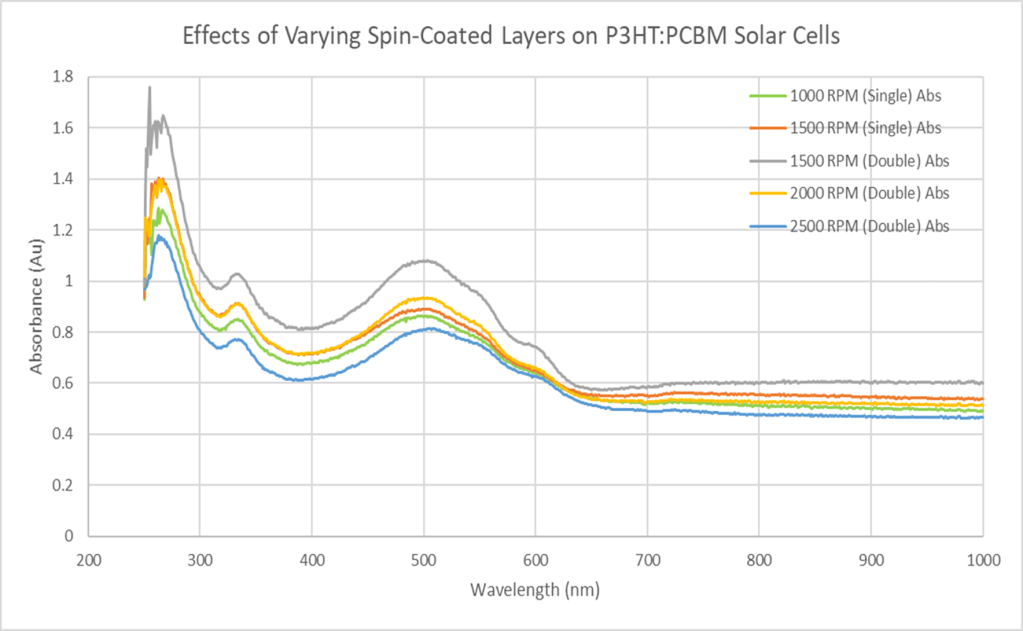

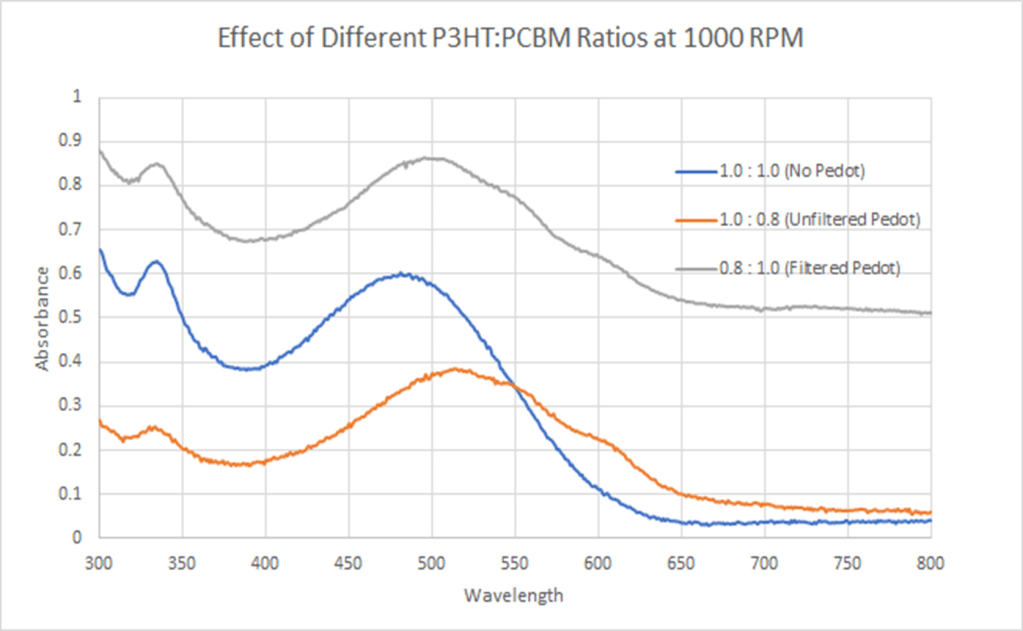

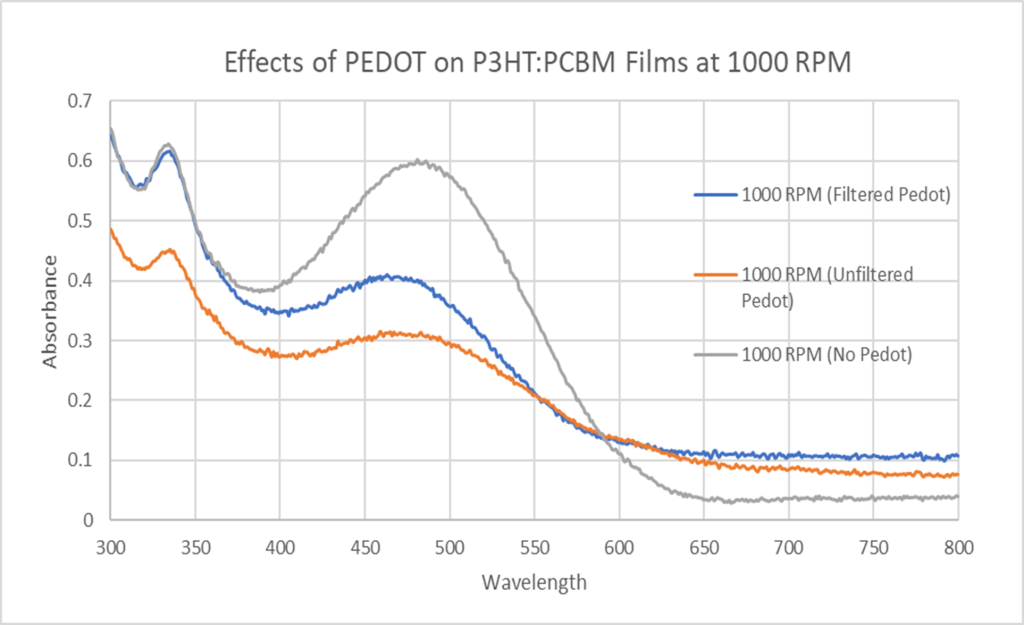

The solar cell studied was made by mixing P3HT Poly(3-hexylthiophene-2,5-diyl) with PCBM (Phenyl-C61-butyric acid methyl ester) and spin coating the solution onto a glass substrate. By varying the ratio of P3HT:PCBM as well as using different spin coating speeds, the impact on the absorbance of the cell was studied. The pi-conjugated conductive polymer P3HT layer acts as the p-type active layer and the fullerene PCBM layer is used as the n-type active layer. Although the cell is promising, it performs lower than the traditional silicon solar cells. The purpose of this research is to discover the ideal mixing ratio and spin-coating speed for the P3HT:PCBM solution. By varying these, the absorbance of the polymer solution can be increased, and therefore the overall efficiency of the cell can be improved.

First, the data was able to demonstrate that the best speed to spin coat at is 1500 RPM. The reason being is because this speed is fast enough to spread the polymer all over the glass slide but not too fast so that it spreads too thinly. Through further testing, the effects of applying PEDOT onto the original solution of P3HT:PCBM was observed. PEDOT would increase the absorbance at wavelengths of 650-800 nm. Filtering and not filtering PEDOT also played a role on the outcome of the absorbance of the solar cell, as the filtered PEDOT would be able to achieve a better absorbance. This is due to the fact that filtering PEDOT decreases the chances of large particles to be drawn out of the solution and therefore a better more even spread is able to create. However, the results show that using PEDOT seems to reduce the peak of P3HT. Multiple layers were also spin coated; however, this reduced the absorbance rather than increase it as predicted. It may be due to the fact that spin coating another layer would push off some of the previous layer instead of adding to it. Finally, through repetition the best mixing time was determined to be a total of 65 hours. Although a lot of conclusions were made, there are still multiple parameters left to be tested and explained such as why PEDOT affects the peak of P3HT.